PBA Systems December 2012 Newsletter

19 12 月 2012

Hits: 1565

In this Edition:

Product Updates

-

- New Models for CVCA and RVCA Voice Coil Actuator Series

- PBA Systems Motors Now Run With Customized Mitsubishi Drivers

Case Studies

-

- High Precision Positioning for Multi-layer Ceramic (MLC) Stacking

- Large-sized High Precision LCD Panel Assembly Machine for Flat Panel Industry

- Low Cost RS-232 Control Using PBA MaxTune and ELMO Servodrives

Events & Other News

-

- Season’s Greetings from PBA Systems

Product Updates

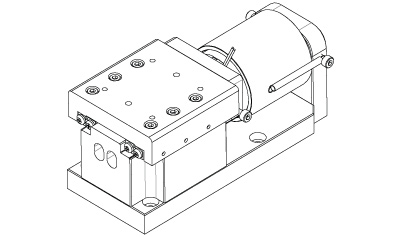

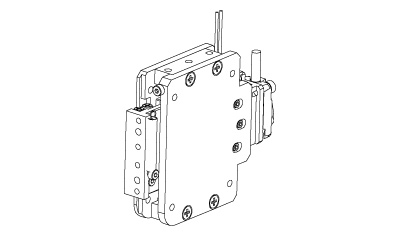

New Models for CVCA and RVCA Voice Coil Actuator Series

PBA Systems introduces its new line of CVCA Voice Coil Actuator Series which uses cross roller bearing instead of normal linear guides for better precision and rigidity. Powered by CVC Circular Voice Coils, the CVCA is Ideal for high speed positioning applications with short stroke.

On the other hand, the new RVCA Voice coil Actuator Series features an improved design with reduced mass. The RVCA is ideal for high speed pick-and-place applications.

Other features of both actuator series are:

- Direct drive, cogging free

- Low moving mass, fast response

- Integrated linear encoder

- Ease of use, plug and play

- Excellent reliability

For more information about these products, click here: CVCA / RVCA.

You can also download 3D drawings of the new products from the PBA Systems Website Downloads.

With the introduction of these new models, old CVCA and RVCA models will be discontinued.

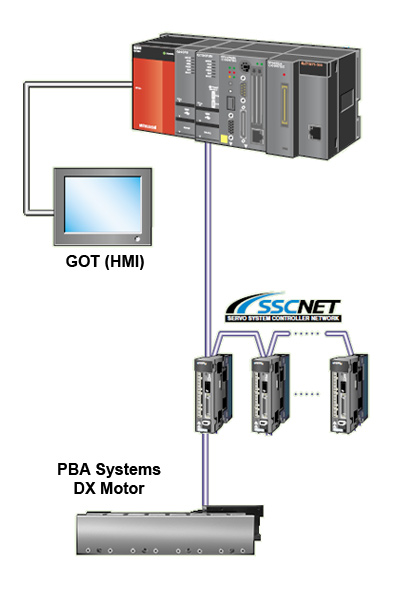

PBA Systems Motors Now Run With Customized Mitsubishi Drivers

PBA Systems has collaborated with Mitsubishi to enable compatibility between PBA Systems DX Motors and Mitsubishi PLC and servo drives. Now customers can combine the reliability and robustness of Mitsubishi PLC systems with the excellent dynamic response of PBA Systems Direct Drive Linear Motors.

The Mitsubishi PLC system is highly expandable with many modules and firmwares for various functions. One of the more useful function would be it’s gantry solution which PBA Systems has implemented in a H gantry application.

| Control | Motor |

|

|

The H-Gantry consists of PBA Systems DX65B-C5P Ironless Linear Motor on the two Y axes and X axis. Mitsubishi motion control solution has separate PID for the two Y axes which ensures that both axes track the motion well with improved repeatability.

To improve accuracy, the error mapping function can be used to store the position error on the axes which can be measured using a laser interferometer. This will greatly increase the accuracy of the system without solely relying on mechanical quality of the system.

Case Studies

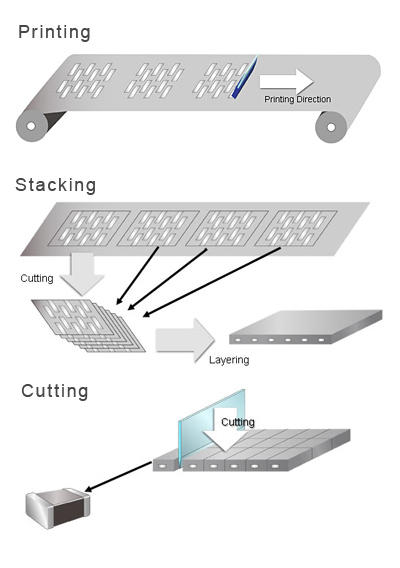

High Precision Positioning for Multi-layer Ceramic (MLC) Stacking

This machine is used for stacking ceramic sheets to produce Multi-Layer Ceramic Capacitors (MLCC). The motion requirements are high speed, accuracy, repeatability and reliability in order to achieve high yield rate and productivity.

300 to 500 ceramic sheets are stacked for every MLCC. Any layer failure will cause the product to fail.

The machine has one 1000mm axis with a motor carriage weight of 300kg. For this axis, the customer was initially using ball screw. However, due to backlash and large friction, the customer was unable to achieve the above requirements and the cycle time was 13 seconds.

Looking for better performance, the customer has decided to switch to PBA Systems DX B Series Ironless Linear Motor.

| Earlier Configuration | Current Configuration |

|

|

PBA Systems DX B Linear Motors have met all the above requirements, and cycle time has been reduced to 9 seconds and the machine is now used in production.

Large-sized High Precision LCD Panel Assembly Machine for Flat Panel Industry

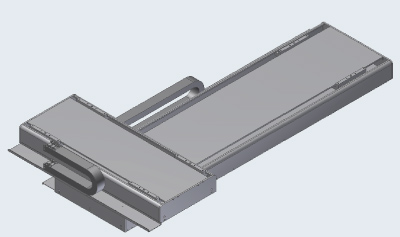

This machine is used for backlight assembly of 60-inch LCD modules in a clean room. The machine has one XY table carrying around 140kg load.The customer requires high accuracy, high speed and high precision motion on the XY stage. For a cost-effective solution that meets all these requirements, the customer has decided to use PBA Systems XY table. The XY table uses PBA Systems LMS Linear Motor Actuators which are powered by the DX B Series Ironless Linear Motors.

| Advantages of PBA Systems XY Table | Disadvantages of Using Ball Screws |

|

|

| Current Configuration |

|

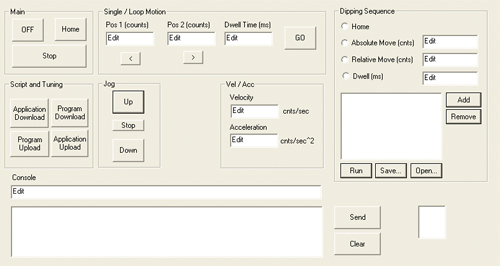

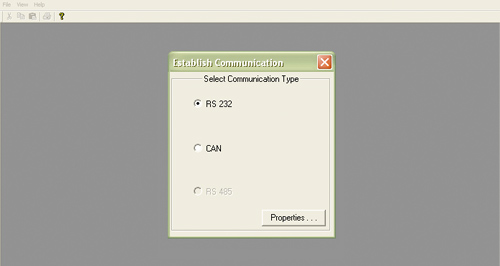

Low Cost RS-232 Control Using PBA MaxTune and ELMO Servodrives

Low Cost RS-232 Control Using PBA MaxTune and ELMO ServodrivesBeing able to control a motor directly through a PC using simple RS-232 or CANOpen command can be very attractive for applications with either single axis or simple multiple axis motion. All that is needed is a PC, MaxTune or ELMO range of servodrives and PBA direct drive motors. When using CANOpen, you will need a CAN Interface.

With this minimal configuration, it is easy to create a GUI (Graphical User Interface) in Windows.

PBA Systems MaxTune Servodrive can simply accept ASCII command from RS-232 and CANOpen. The programmer will just have to refer to the command list available (see PBA Systems Website Downloads) and send it in ASCII format using any programming language.

ELMO Servodrive has provided a library for Visual C++ to send commands to the servodrive through either RS-232 or CANOpen. It even supports synchronization between multiple axes using “Position, Velocity, Time” (PVT). However it is not recommend to use PVT since Windows is not real-time and due to the bandwidth limitation of CANOpen.

PBA Systems has implemented many GUIs for its customers. An example GUI is shown on the right for the Dip-Coating Machine done using ELMO Cornet and PBA DX20B-C3.

Contact PBA Systems if you are interested in implementing this highly convenient and low-cost solution.

| RS232 and CANOpen Control with PBA MaxTune | RS-232 and CANOpen Control with ELMO |

|

|

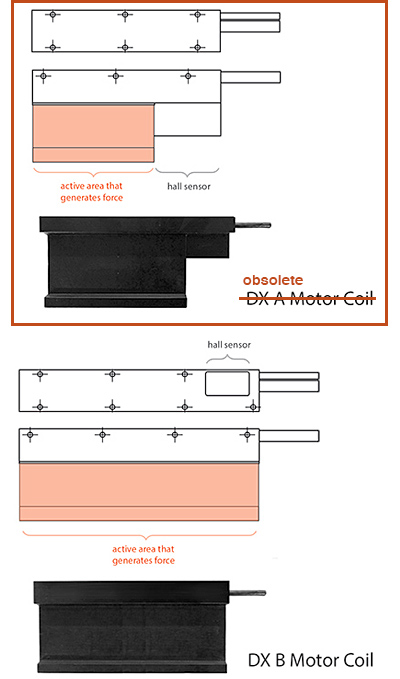

DX A Type Linear Motor – Obsolete

PBA Systems would like to regretfully inform our customers that production of all DX A type linear motors will cease effective November 1, 2013. 15 years after it was first launched, the DX A linear motor is now obsolete. It’s replacement, the DX B Ironless Linear Motors has slightly different motor coil dimensions, with the advantage of a longer effective stroke. The magnet track dimensions and mounting holes remain the same.

The diagram below illustrates the differences between the DX A and DX B motor coils. Complete specifications of the DX B Series Ironless Linear Motors are available at https://www.pbasystems.com.cn

Events & Other News

Season’s Greetings from PBA Systems

To our clients, distributors and business partners who have made our progress possible, we extend our warmest wishes for the Holiday Season and a prosperous and peaceful New Year!

Please note that PBA Systems will have a holiday shutdown from Dec 24, 2012 to Jan 1, 2013. Business will resume as usual on Jan 2, 2013.

For more information on any of the products featured above, please contact:

PBA Systems Pte Ltd

2, Woodlands Sector 1, Woodlands Spectrum 1, #03-23, Singapore 738068

Tel +65 6576 6767 | Fax +65 6576 6768 | Email sales_cn@pbagroup.net | Website www.pbasystems.com.cn

Disclaimer: Every care has been taken to ensure the correctness of the information contained in this newsletter but no liability can be accepted for any errors or omissions. Copyright reserved. This newsletter or parts thereof may not be reproduced without PBA Systems’ permission.